What is the surface treatment technology of stainless steel spring?

Date:2019-07-12 Author: click:

What is the surface treatment technology of stainless steel spring?

Stainless steel spring is a kind of corrosion resistant, high temperature resistant, non-magnetic elastic element, suitable for chemical machinery, electronics and other industries of the working environment. Generally speaking, springs should have high elastic limit, fatigue limit, impact toughness, good heat resistance and corrosion resistance. Stainless steel springs should be made strong or polished to improve the bearing capacity and surface finish of the springs. The specific surface treatment method is as follows:

1. Remove oil and deoxidize stainless steel spring:

Method 1. Soak the stainless steel spring in a plastic container, dilute the metal cleaning agent with water, soak time should not be too long, until the surface of the spring without oil and oxidized skin, in order to restore the natural color of the metal, soak the stainless steel spring with water, dilute the metal cleaning agent with water, the stainless steel spring into the plastic container. Stainless steel like this? There is a matte effect on the surface of the spring.

Method 2. In ultrasonic equipment, the ratio of cleaning agent to water is about 1:30. When the spring surface without oil, no oxidation skin to restore the true color of the metal, you can immediately clean the surface of the stainless steel spring with water, stainless steel spring surface can achieve matte effect.

Both of the above methods can be used for high precision springs.

Method 3. After grinding and polishing cleaning agent in coarse abrasive, spring vibration polishing machine or hexagonal roller, the scratches on the spring surface disappear and the finish of the spring surface is improved. This method is not suitable for high-precision and easily wound springs.

2. Glass stainless steel spring:

The brightener B polishing into vibration polishing machine or rough abrasive hexagonal roller (the volume ratio of spring and fine abrasive is 1:3, the amount of brightener B is about 1%--2% of the weight of the spring, the longer the brighter), clean and dry with water, so that the surface of the stainless steel spring bright such as nickel plating, never fade.

Website of this article:http://en.szchengfa.com/news/424.html

key word:医疗弹簧

Recent Browsing:

Related products:

Related news:

- Joint Laboratory of Medical Interventional Devices unveils the establishment of a ten-billion dollar industry to forge a "Chinese business card"

- "Rise of China" 20220418 | Du Zhisheng: the perfection of small spring applications

- "Rise of China" 20220418 | Du Zhisheng: the perfection of small spring applications

- Inclined ring spring contact seal characteristics

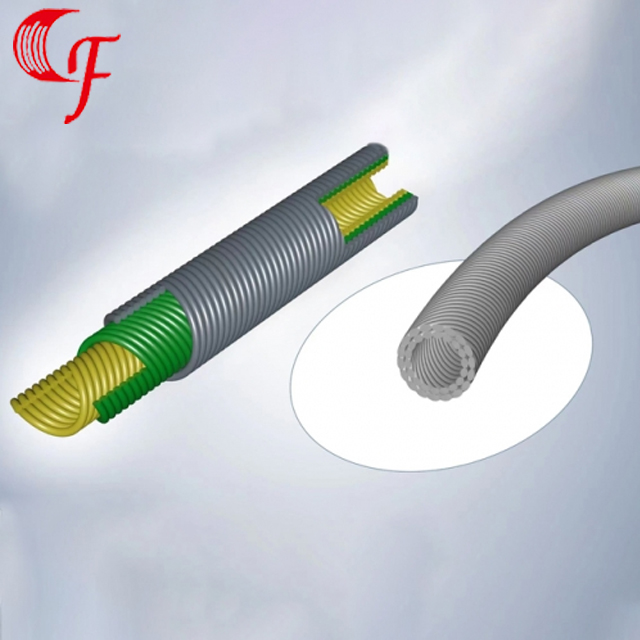

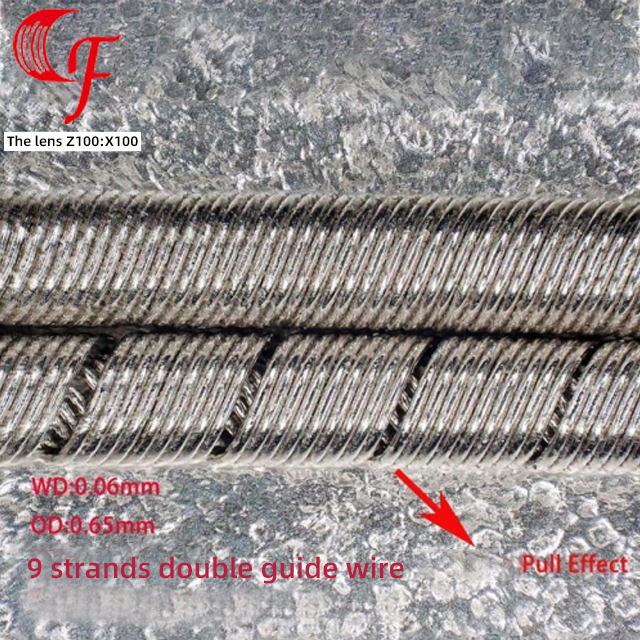

- What is the structure of guide wire spring

- How to use oblique round spring correctly

- Medical springs: surface treatment of spring equipment to extend service life

- Tu’s ChengFa and Shenzhen Institute of Advanced Technology set up

- Joint Laboratory of Medical Interventional Devices unveils the establishment of a ten-billion dollar industry to forge a "Chinese business card"

- The team of Xiaojing Gong at Shenzhen Advanced Institute published the results of the first OCT-ultrasound dual-mode endoscopy and endometrial biopsy evaluation in small animals