Automobile spring material selection

Date:2019-07-09 Author: click:

Automobile spring material selection

The automobile spring is subjected to various stresses in the process of automobile driving, among which repeated bending stress is the main stress, and fatigue failure is the main stress. Therefore, the spring steel should have higher elastic limit, good elastic attenuation resistance and high yield ratio. In order to prevent fatigue and fracture under alternating stress, the spring should have high fatigue strength and corrosion resistance. The choice of automobile spring material is: 20 Cr, 40 CrNiMn, 60Si2Mn, 65 Mn. The properties and uses of these four materials are compared below.

1, 20 Cr

This steel is one of the largest alloy structural steels in China and has a wide range of uses. The hardness is higher. Compared with carbon steel with the same carbon content, the steel has better hardening, strength and toughness. In order to improve the wear resistance of die steel, carburizing is often carried out (note: the grain of the steel has a tendency to grow up during carburizing), and then quenching and low temperature tempering are carried out to ensure that the die surface has high hardness, high wear resistance and good central toughness. It is often used to manufacture carburized parts or cyanide parts with small section, simple shape and fast speed, such as piston pin, shaft, etc., and can also be used in tempering steel parts.

2, 40 CrNiMn

Quenched and tempered steel has high strength, toughness, good hardening and overheating stability, but high sensitivity to white spots, high tempering brittleness. Poor weldability, need to preheat before welding, welding should eliminate stress, quenching and tempering should be used. Application: Generally manufacture important parts with high strength and good plasticity. After nitriding, manufacture important parts with special performance requirements, such as shafts, gears, fasteners, etc., which can be used for low-temperature quenching or tempering of ultra-low strength steel.

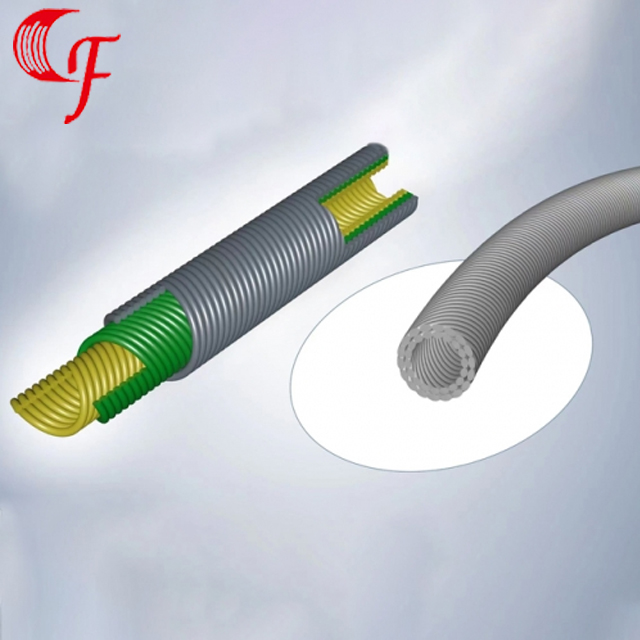

3, 60 si2mn

Due to the high silicon content, the strength and elastic limit are better than the high tempering stability of 55Si2Mn, the hardening is not high, easy to decarbonize and graphitization. It is mainly used in the plate springs and coil springs of automobiles and tractors, and also used in the manufacture of important springs and wear-resistant springs that work under alternating load and high stress.

4, 65 MN

The addition of manganese in steel is 0.8%≤1.2%, which improves the hardness and comprehensive performance of steel and reduces the decarbonization tendency, but there is a tendency of superheated tempering brittleness, which is easy to produce quenching crack. Besides, manganese steel has low price and rich resources, and can be used for common die springs. Cold stamping die punch; Spring ring, valve spring.

Website of this article:http://en.szchengfa.com/news/401.html

key word:超精密弹簧,医疗弹簧

Recent Browsing:

Related products:

Related news:

- Inclined ring spring contact seal characteristics

- What is the structure of guide wire spring

- Joint Laboratory of Medical Interventional Devices unveils the establishment of a ten-billion dollar industry to forge a "Chinese business card"

- The team of Xiaojing Gong at Shenzhen Advanced Institute published the results of the first OCT-ultrasound dual-mode endoscopy and endometrial biopsy evaluation in small animals

- Medical springs: surface treatment of spring equipment to extend service life

- Tu’s ChengFa and Shenzhen Institute of Advanced Technology set up

- "Rise of China" 20220418 | Du Zhisheng: the perfection of small spring applications

- Joint Laboratory of Medical Interventional Devices unveils the establishment of a ten-billion dollar industry to forge a "Chinese business card"

- How to use oblique round spring correctly

- "Rise of China" 20220418 | Du Zhisheng: the perfection of small spring applications